Our new dealcoholization system

21.07.2021

1 Min Reading Time

Demand is rising and we’re responding: our new dealcoholization system makes us ready for the challenges of the future. You can read why here.

Nonalcoholic beers are all the rage. Gone are the days when nonalcoholic beer was passed off as an unappealing alternative for drivers. Recent decades have seen a lot of tinkering with the brewing process, and the taste has improved significantly at practically all breweries in the past few years.

Nonalcoholic beer is now its own category

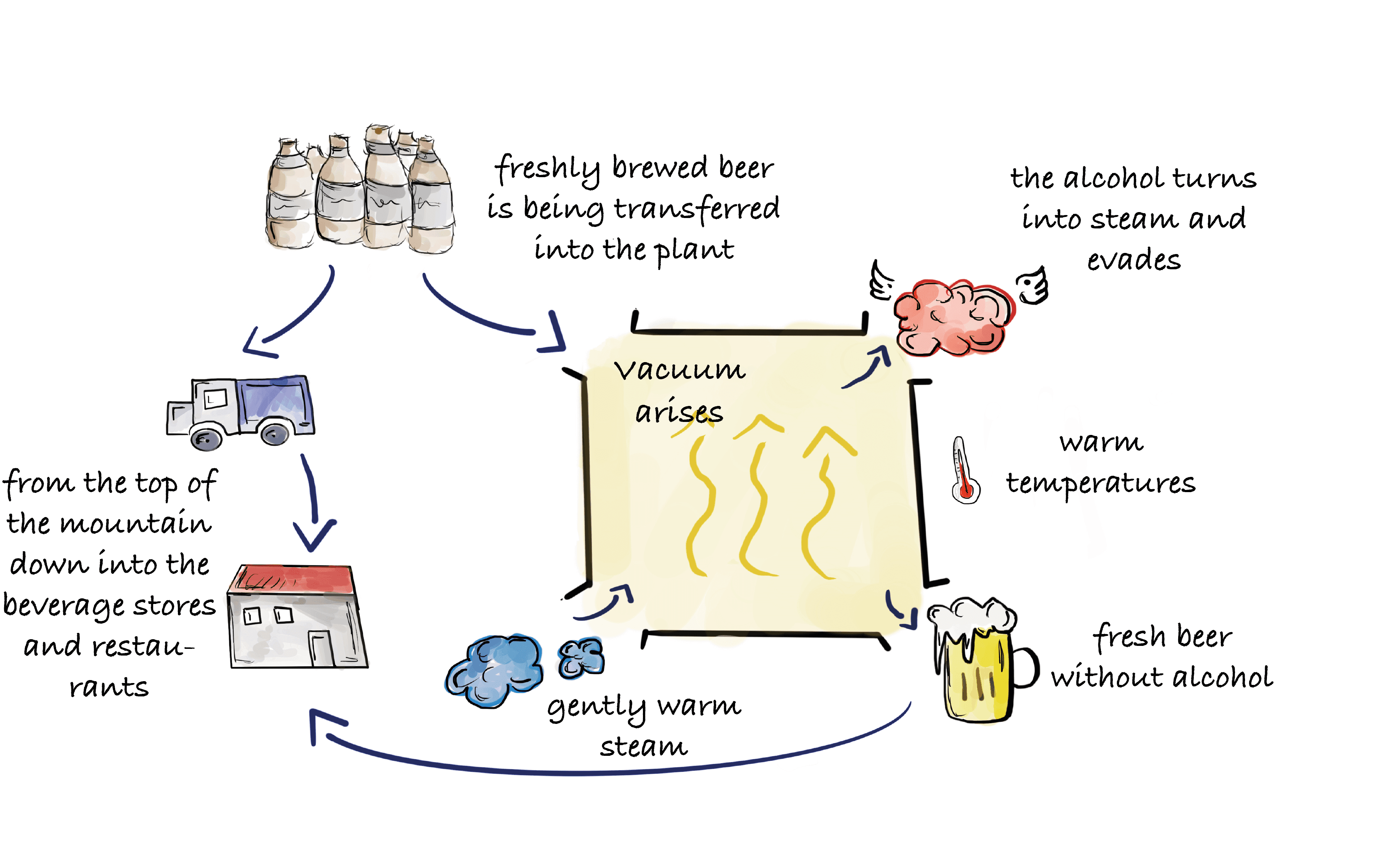

This has put nonalcoholic beer into its own category, with a steadily growing number of fans and admirers. We obtained our first dealcoholization system over thirty years ago – a brand-new development from the Technical University at the time. The technology it uses is still one of the leading methods for producing outstanding quality in nonalcoholic beers: falling-film vacuum evaporation. This is a particularly elaborate but also gentle process for separating the alcohol from a fully fermented and matured beer by heating in a vacuum.

Special process produces great tasting nonalcoholic beer

“For us, this is the best way to offer consumers a taste sensation that comes closest to beer with alcohol,” explains Tobias Zollo, First Brewmaster. There are other methods, such as stopped fermentation. “In that method, fermentation of the beer is stopped before any alcohol has been produced. The result is that the malt sugar is not consumed, the beer tastes sweeter and has many more calories,” as Zollo explains the most common process used by many other breweries. We chose falling- film evaporation mostly because it benefits the taste, and we’re glad the new investment has now doubled our capacity. But that’s not all: “This system was custom-developed and constructed to meet our specifications and needs so that we brewers can control all the production parameters we think are important – we’re really proud of it,” Zollo adds with a smile.